Steel slag is formed under the temperature of 1500 ~ 1700 ℃, which is in liquid form. After cooling down is becomes a massive, general industrial solid waste of dark grey or dark brown color. The steel slag is mainly composed of calcium iron, silicon, magnesium and a small amount of aluminum oxide, manganese, phosphorus, etc. The main minerals are tricalcium silicate, dicalcium silicate, calcium magnesium olivine rhodonite, iron, calcium magnesium aluminate calcium and silicon, magnesium, iron, manganese, phosphorus oxide formation of solid solution and it also contains a small amount of free calcium oxide and metallic iron, fluorapatite, etc.. Some areas because of containing titanium and vanadium ore, the steel slag slightly also contain these ingredients. There steel slag components because of furnace type, steel grade and content of each stage of the furnace steel smelting, have bigger difference.

Steel slag is not a waste, since the early 70s, the United States is the first country to fully utilize all the annual emissions of 17 million tons of steel slag. At present, most of the steel slag in Germany has been used, steel slag utilization is about 60% in the UK, France, Japan reaches at approximately 50%, however China is only about 10%.

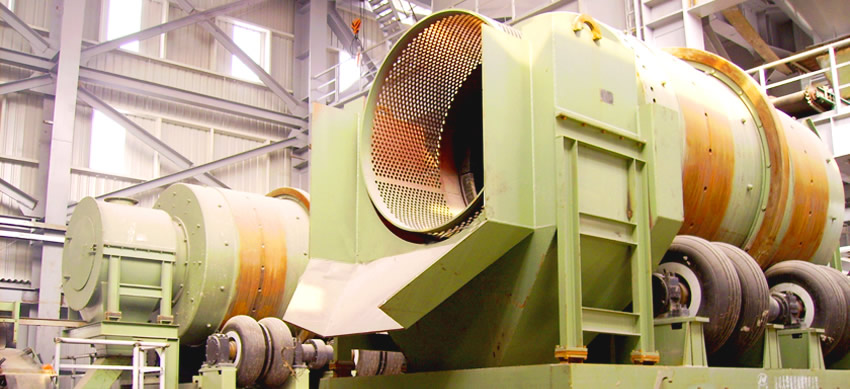

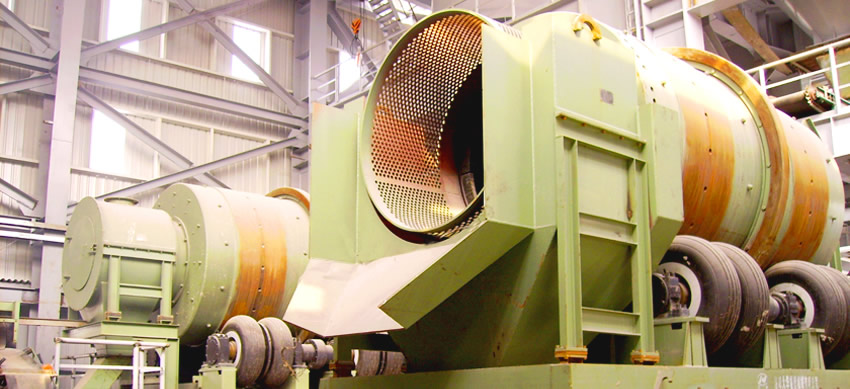

Domestic steel manufacturer produces the steel slag which could be piled up to occupy a large amount of farmland and land, causing serious environmental pollution and resource waste. Luoyang Dahua Heavy Machinery Co., Ltd with a strong sense of social responsibility, designs a complete set of steel slag comprehensive recycling production line after steel slag crushing, through baking drying, sieving, magnetic separation of fine crushing grinding classification and grade of wet magnetic separation, pellets manufacturing process, such as building aggregate, steel slag cement, etc. It can effectively utilize the steel slag and make sure no waste left, which brings huge economic benefits and eliminates the potential danger of environmental pollution. Luoyang Dahua Heavy Machinery Co., Ltd. is in service for customers to boost their business by offering reliable project solutions.