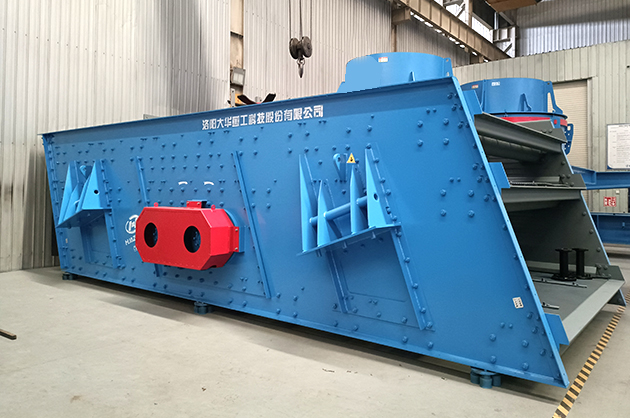

BP Primary Impact Crusher

Feed size: 600-1400 (mm)

Processing Capacity: 55-1100 (t/h)

Application Fields: water conservancy and hydropower, construction, highway and railway, etc.

Applied Material: medium soft rock

Tel.: +86-379-62669977 E-Mail: [email protected]

Overview

Our company applies France latest technology and manufactures BP series primary impact crusher. The machine is mainly for coarse crushing. The maximum feed size can reach 1400mm when crushing materials with compression strength less than 150MP, which can replace the primary crushing equipments such as jaw crusher, cycle machine etc.

Product Features

1.The new type rotor body can provide extremely high rotational inertia and crushing force of hammer to thereby enhance the first pass yield.

2.The distinct design of “S” type of hammer makes the shape of its crushing surface keep almost the same during its life circle and thus ensure a stable configuration.

3.The novel fixed form without bolts in hammer makes it easier and more efficient to replace it.

4.The small number of wearing parts ensures a high passing rate and at the same time lowers the cost of spare parts for users.

5.The stop-motion mechanism makes it much safer and easier to replace wearing parts.

Working Principle

Impact crusher is a kind of crushing machine that uses the plate hammer of the high speed rotating rotor to crush the materials at a high impacting crushing force. When the materials get into the action area of plate hammer, they are crushed by the hammer at a high speed. The crushed materials are thrown to the impact plate along the tangential direction to crush again. Then they are rebounded from the first impact plate to the action area of the plate hammer and enter into the second impact plate to repeat the above process. During this process, materials also crash with each other. This process will proceed repeatedly until the material are crushed to the required granularity, and then discharged from the clearance between impact plate and plate hammer.

Technical Parameters

| Model | Max. Feed Size(mm) | Capacity(t/h) | Power(kw) | |||

| 0-30mm | 0-50mm | 0-100mm | 0-150mm | |||

| BP22 | <800 | 80-155 | 115-225 | 185-260 | 220-300 | 160 |

| BP33 | <1000 | 125-220 | 180-300 | 260-360 | 320-420 | 250 |

| BP44 | <1200 | 135-300 | 220-420 | 375-550 | 480-700 | 2×200 |

| BP55 | <1400 | 175-400 | 290-550 | 780-860 | 675-1100 | 2×(250-375) |

Customer Cases