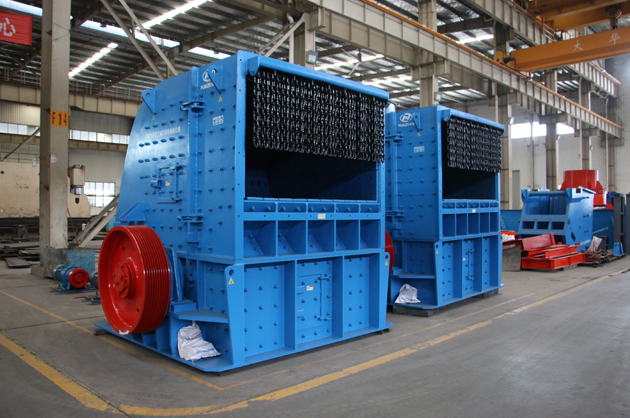

C Series Jaw Crusher

Max. Feed Size: 680-1200 (mm)

Processing Capacity: 185-1300 (t/h)

Application Fields: metallurgy, mining, chemical, cement, construction, etc

Applied Material: limestone, dolomite, phosphate ore.

Tel.: +86-379-62669977 E-Mail: [email protected]

Overview

C Series Jaw Crushers are new kind of products manufactured by our company, cooperating with the technology of ALTAIRAC France. They are jaw crushers with high throughput, low energy consumption, reliable structure and easy maintenance, being the preferred primary crushers for various rocks.

Product Features

1. This is new technology has the features of excellent motion characteristics, special chamber design which saves more than 10% energy consumption and has more than 15% bigger throughput.

2. Unique crushing chamber design makes the availability of jaw plate much higher. Jaw plate can be switched four times that achieves evenly attrition. This advances the material availability and prolongs service life.

3. The teeth on jaw plate in crushing chamber faces to faces (swing jaw plate and fixed jaw plate), which is good for crushing hard materials.

4. The structure design of adjustable transmission angle makes higher capacity in the same discharge outlet.

5. Fixed jaw plate and swing jaw plate can be changed for each other. This design will save user’s spare consuption and the assembly is more convenient.

6. The hydraulic adjustment of double-jack for discharge outlet is convenient and labor saving.

7. Swing jaw and main frame can be disassembled easily which is convenient for transportation.

Working Principle

Electrical motor drives the belt wheel to make the swing jaw move following the specific track by eccentric shaft. After the materials enter into the crushing chamber, they are crushed between the two jaw plates by impacting, bending, and striking, and then discharged from the discharge opening.

Technical Parameters

| Model | Inlet Size(mm) | Max. Feeding Size(mm) | Discharge Gap(mm) | Capacity(t/h) | Power(kw) |

| C1008 | 1020×800 | 680 | 65-250 | 185-500 | 110 |

| C1210 | 1160×1050 | 850 | 75-275 | 270-810 | 132 |

| C1412 | 1400×1200 | 1000 | 95-300 | 390-950 | 185 |

| C1615 | 1610×1400 | 1120 | 120-300 | 470-1150 | 220 |

| C1815 | 1800×1500 | 1200 | 125-325 | 630-1300 | 355 |

Customer Cases