PFQ Series Vortex Strong Impact Crusher

Discharge granularity: 25-50 (mm) [80-90%]

Processing Capacity: 46-670 (t/h)

Application Fields: cement, construction, chemistry, highway and railway.

Applied Materials: basalt, andesite, cobble, granite.

Tel.: +86-379-62669977 E-Mail: [email protected]

Overview

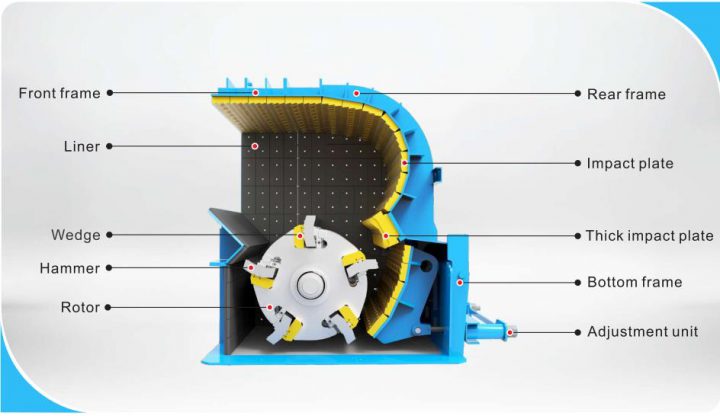

PFQ series vortex strong impact crusher is high efficient impact crusher developed by our company. This crusher is applied to primary, secondary and fine crushing of a variety of materials with compression strength not more than 250Mpa.

Product Features

1.The unique structure contains large vortex crushing cavity and three crushing sections(P,S,T section) and create higher crushing efficiency and productivity.

2. It has the features of unique structure, easy operation, high-efficiency and saving energy, good product shape-cubic like, adjustable discharge size, simplifying crushing process, saving cost etc.

Working Principle

Electrical motor drives through V-belts and makes the rotor run at high speed. Materials will be fed into the crushing chamber from feed inlet, and be struck by the plate hammer which rotates at high speed. The materials are thrown up to the dentate reaction plate on the top of the crushing chamber and then falls down, the thrown-up and falling-down materials are crushed by striking with each other. The big incompletely crushed materials will form big stress and bending force at the interaction of hammer and thick impact plate in P crushing chamber, even the hard crushed materials will be broken and enter into the following S and T crushing chamber. The materials in these two crushing chambers can be medium and fine crushed by striking, impacting, bending and extruding, then discharged out of the machine.

Technical Parameters

| Model | Max. Feed Size (mm) | Discharge Size(mm) | Capacity (t/h) | Power (kw) | |

| <150MPa | <250MPa | ||||

| PFQ1108 | 300 | 150 | 30 | 50-100 | 75 |

| PFQ1110 | 400 | 200 | 35 | 80-150 | 110 |

| PFQ1113 | 400 | 200 | 40 | 100-160 | 132 |

| PFQ1310 | 400 | 200 | 40 | 140-200 | 160 |

| PFQ1313 | 400 | 250 | 40 | 180-260 | 200 |

| PFQ1315 | 400 | 300 | 40 | 200-300 | 250 |

| PFQ1320 | 400 | 300 | 40 | 300-400 | 2×160 |

| PFQ1520 | 500 | 400 | 40 | 350-550 | 2×250 |

| PFQ1523 | 600 | 400 | 40 | 500-680 | 2×315 |

Customer Cases