At present, the structure of the gravel aggregate industry is facing upgrading and transformation, and is developing towards green, environmental protection and sustainable development. The importance of the gravel aggregate is further highlighted. Although there is a shortage of sand and gravel in the market, can sand and gravel really sell for a good price? Of course not, the products on the market are being updated every day, trying to attract the attention of customers. The sand and aggregate industry is no exception. Whether the sand can sell a good price depends on the quality of the sand. Nowadays, machine-made sand is widely used in infrastructure construction. Sand washing is the last link of the sand production line. The main function of the sand washing machine is to clean sand, remove impurities and sludge. Therefore, the sand washing step is particularly important in the aggregate production line. Let's take a look at why the sand washing machine can improve the quality, how much is sand washing machine?

The quality of the sand washing machine is now a very important point in the sand and stone industry. The sand washing link is an indispensable part of the sand and stone production line, because the sand and stone undergo a fierce collision in the process of crushing sand, plus the soil content of the stone The amount of sand produced often contains stone powder and mud powder, so after the sand washing process, the excess stone powder is washed away, the purity of the sand will increase, the quality will rise, and the quality will increase, then the price of the sand sold will certainly. The high and clean quality sand will increase the price.

Advantages of Luoyang Dahua Sand Washing Machine

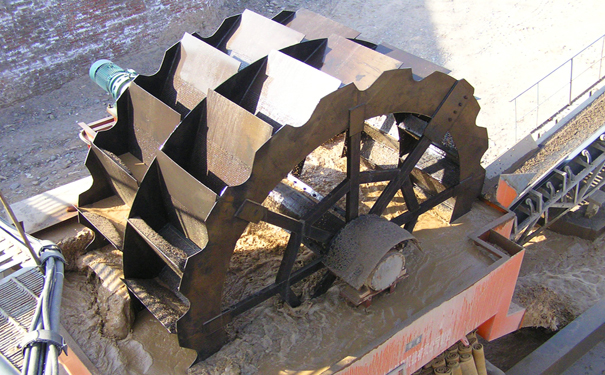

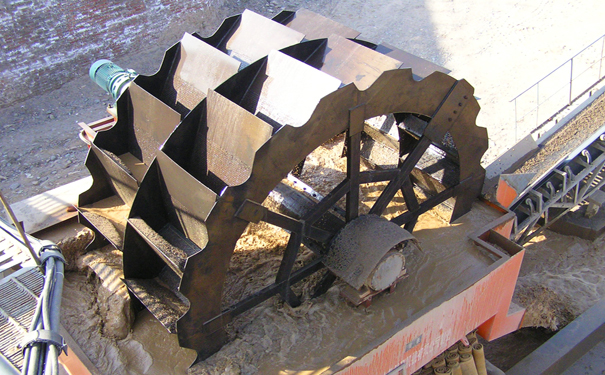

When the DXS series bucket wheel sand washing machine is working, the motor drives the impeller to slowly rotate after decelerating through the V-belt, reducer, and gear. Impurities covering the surface of the sand and gravel, and at the same time destroying the water vapor layer covering the sand grains to facilitate dehydration; at the same time, water is added to form a strong water flow, and impurities and small foreign bodies with a small specific gravity are promptly taken away, and discharged from the overflow tank to complete the cleaning function. The clean gravel is taken away by the blades, and finally the gravel is poured from the rotating impeller into the discharge trough to complete the cleaning of the gravel. This machine is widely used in the sand washing operation in the aggregate processing industry, which can effectively remove the stone powder and debris mixed in the sand and improve the quality of the sand.

1. Large processing capacity and low production cost. The output of DXS series sand washing machine is ideally up to 350 tons per hour, which basically meets the sand washing capacity needs of our customers; at the same time, the machine has low power and low power consumption, which can effectively save production costs.

2. The structure is simple and the failure rate is low. The structure is simple, the bucket wheel transmission device is placed on the water surface, which is protected from the damage of water and sand and mud, and the phenomenon of bearing damage caused by water immersion, sand and pollutants is greatly avoided.

3. Cleaning, dehydration and classification are all in one, and the degree of cleaning is high. The equipment has three functions: cleaning, dehydration and classification: when working, the impeller drives the sandstone to grind each other to remove impurities covering the surface of the sandstone, at the same time destroy the water vapor layer covering the sandstone, and complete the cleaning under a strong water flow Exclusion function.

4. The equipment is stable and the sand washing effect is good. The sand washing machine rotates steadily, the water flow can be adjusted to control the loss of fine sand and stone powder, and a good sand washing effect is achieved, with a large processing capacity and low energy consumption.

For more information, you can click: www.lydhchina.com