With the fierce development of infrastructure construction, the demand for gravel aggregates continues to increase, the supply of natural sand is insufficient, and machine-made sand fills this gap. The complete set of equipment for machine-made sand and gravel production line usually includes crusher, sand making machine, vibration equipment, supporting equipment, etc. Although the source of machine-made sand is wide, raw materials such as tailings and construction waste are in compliance with the resource recycling policy, but during the process of treatment, care should be taken to avoid pollution. The production of machine-made sand is hot, but how to achieve environmentally friendly production?

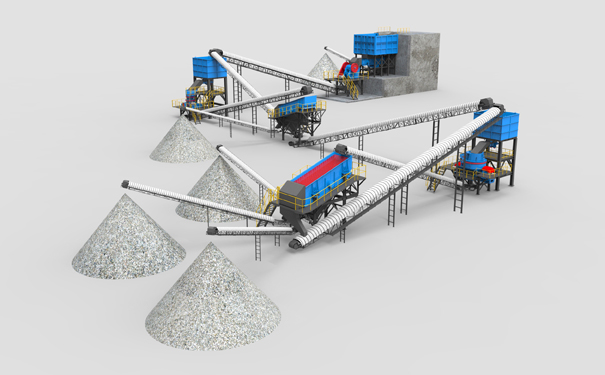

The equipment configuration of the gravel aggregate production line generally adopts two stages of coarse crushing and fine crushing, and some stones require three stages of crushing or shaping, and then sieving. The equipment usually used for coarse crushing includes gyratory crusher and jaw crusher, some use hammer crusher or impact crusher, medium crushing adopts impact crusher or cone crusher, and fine crushing and shaping is commonly used vertical impact crusher (Sand making machine).

The technological process of the whole sand and gravel production line is: the large stones are sent to the vibrating feeder through the dump truck, and are roughly broken by the jaw crusher, and the stones come out into the cone machine or the impact crusher for the second crushing. After being sieved by the vibrating screen, the product that does not meet the specifications of the finished product is returned to the cone crusher and crushed again, and finally it is divided into finished products of different sizes by the vibrating screen.

For sand and gravel factories, environmental protection is mainly limited to the three aspects of dust, noise and sewage.

1. Closed production (A large amount of environmental protection can be achieved.)

(1) The installation of multi-effect dust removal equipment is necessary. At the same time, the production line adopts a partially enclosed design, and the dust cover is used to collect the generated dust, which can reduce the dust pollution to a large extent;

(2) The closed panel house design can significantly reduce noise pollution and one of the important conditions for environmental protection of the gravel production line.

2. The sand crushing equipment is normal, the production line already exists, there is no closed workshop, and there are no environmental protection measures.

If the sand and stone plant is built for a period of time and the equipment functions normally, but there are no environmental protection measures, you need to consult a professional sand making equipment manufacturer to design a set of environmentally friendly production plans based on the original production line.

(1) Auxiliary equipment for environmental protection: equipped with a dust collector or equipped with a sprayer for dust removal, the conveying equipment and screening equipment can be covered with sheds as required, and the pollution is controlled within a small range, which meets the national sand standard.

(2) Noise control: In areas with strict noise decibel control, closed workshops can be built, and shielding devices or mufflers can be added to effectively avoid noise pollution.

(3) Wastewater sludge: In the process of sand washing, machine sand can be used to build sewage sedimentation tanks, sand washing wastewater can be recycled, and the precipitated sludge and waste soil can also be used for the reclamation of mine cushions. Continue to be used for sand washing.

For more information, you can click: www.lydhchina.com