Machine sand is relative to natural sand, such as river sand. Natural sand is mainly caused by the impact of natural forces, such as river sand, sea sand and mountain sand. Machine sand refers to rock particles with a particle size of less than 4.75 mm made by mechanical crushing and sieving after decontamination treatment. Limestone is an industrial rock with a wide range of uses and a large number of industrial uses. It is widely used in metallurgy, chemical industry, construction, building materials, environmental protection, agriculture, food and other fields. Machining sand using limestone has been widely used in industry. Adopting limestone processing sand making machine can effectively increase the output of limestone lump ore, reduce the amount of limestone waste residue, and has obvious energy saving and emission reduction effects.

Limestone sand production process

The processing of limestone is mainly crushing, grading and producing lime, slaked lime, precipitated calcium carbonate, carbon dioxide, etc. Limestone generally adopts dry pulverization process. For metallurgy and road limestone, the ore can be crushed and screened.

Limestone or limestone raw ore grade can generally meet the requirements of various industrial sectors, and generally only requires simple ore washing, that is, limestone or limestone ore is treated by ore washing-crushing-screening or classification.

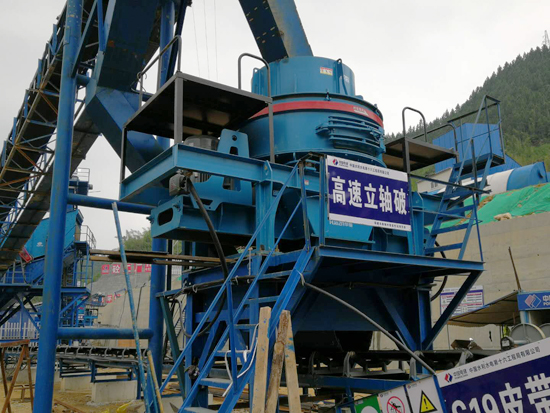

The process flow of machined sand production is: feeding → primary crushing → secondary and fine crushing → screening → sand making → screening → sand washing → finished product.

The required equipment is vibrating feeder, jaw crusher, impact crusher, cone crusher, vibrating screen, sand making machine, sand washing machine and conveyor equipment.

Advantages of Limestone Sand

Limestone machined sand is made from waste excess resources such as waste, waste slag, and stone powder from the limestone quarry. It is made by mechanical crushing, washing and screening. The limestone machined sand processed according to the above process has the following advantages:

1. Machine sand can effectively and stably control technical indicators such as sand particles according to national standards and engineering quality requirements, and meet engineering technical requirements.

2. The particle and fineness modulus of machine sand can be adjusted. According to the needs of the project, the fineness modulus and particles of machine sand can be adjusted by combining the good points of the base material and the requirements of concrete.

3. The shape of the machined sand particles is multi-angular, and the surface is rough, which is conducive to bonding with cementitious materials such as cement and to improve the strength of concrete.

4. The production of machine-made sand can be combined with the production process of crushed stone, which is conducive to the comprehensive utilization of good mineral resources and reduces pollution, thereby greatly reducing the production cost of machine-made sand.

Of course, the lithological rocks used in the preparation of sandstone aggregates in various regions also need to be adapted to local conditions, depending on the specific situation!

For more information, you can click: www.lydhchina.com