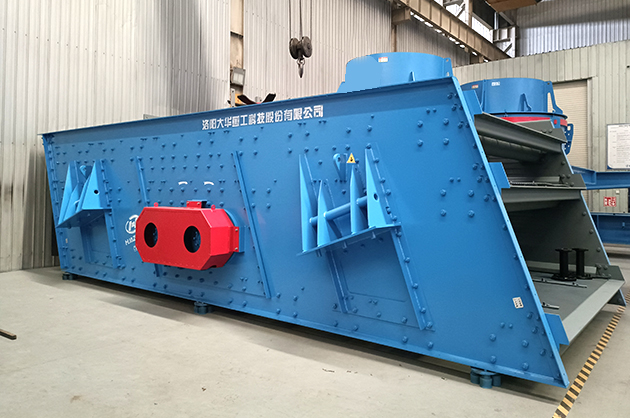

Eccentric Block Circular Vibrating Screen

Max. Feed Size: 200 (mm)

Processing Capacity: 80-900 (t/h)

Application Fields: metallurgy, construction, coal, chemical industry.

Applied Material: it is suitable for all kinds of materials.

Tel.: +86-379-62669977 E-Mail: [email protected]

Overview

The circular vibrating screen is used for material screening and grading, also is applicable for metallurgy, chemical industry, coal and building, etc. There are two types: hanging and seating. The models have monolayer, double-layer, three-layer, autogenous-centre vibrating screen and linear vibrating screen, etc.

Product Features

1. Two sructure types——three layer and four layer.

2. The frequency, amplitude and leaning angle of screen can all be adjusted.

3. External eccentric block vibrator structure is designed and applied.

Working Principle

Eccentric block circular vibrating screen is mainly composed of screen box, sieve, vibrator, damper spring and so on. The vibrator is placed on the side plate of screen box, and rotates by the motor. It generates centrifugal inertia force that makes the screen box vibrating. The electromotor drives the coupling to make the eccentric block of exciter rotating at high speed. The rotating eccentric block generates large centrifugal force, and makes the screen box do circular movement in certain vibration amplitude. The material that is smaller than the sieve will drop down, thus realize the purpose of classifying.

Technical Parameters

| Model | Layer | Mesh Size(mm) | Double Amplitude | Vibrating frequency | Max. feed size(mm) | Capacity(t/h) | Power(kw) |

| YK1845 | 2/3 | 3-150 | 7-8 | 800 | 200 | 55-450 | 22/30 |

| YK1854 | 1/2/3/4 | 3-150 | 7-8 | 800 | 200 | 60-480 | 22/30/30/37 |

| YK1860 | 1/2/3 | 3-150 | 7-8 | 800 | 200 | 80-500 | 22/30/37 |

| YK2160 | 1/2/3/4 | 3-150 | 7-8 | 800 | 200 | 100-750 | 30/37/45/37 |

| YK2460 | 1/2/3/4 | 3-150 | 7-8 | 800 | 200 | 120-880 | 30/37/45/45 |

| YK2475 | 1/2/3/4 | 3-150 | 7-9 | 800 | 200 | 150-950 | 37/45/55/2×37 |

| YK2773 | 1/2/3/4 | 3-150 | 7-9 | 800 | 200 | 150-1100 | 37/45/55/2×37 |

| YK3060 | 1/2/3 | 3-150 | 7-9 | 800 | 200 | 150-900 | 37/45/55 |

| YK3073 | 1/2/3 | 3-150 | 7-9 | 800 | 200 | 150-1100 | 44/55/2×30 |

| YK3280 | 2/3 | 3-150 | 7-9 | 800 | 200 | 150-1200 | 2×(30/37) |

| YK3680 | 2/3 | 3-150 | 7-9 | 800 | 200 | 200-1200 | 2×(45/45) |

Customer Cases