In recent years, accompany with the increase of domestic and world-wide infrastructure constructions demands, various of stone crushing machines are in service for sand-making projects. Due to the difference of geographical features, aggregates characteristics, customer demands and working conditions, it is essential to choose the most suitable equipment to undertake specific mission to fully exercise equipment performance.

Based on the concept of “All for Customer’s Service”, Dahua’s research team take the advantage of their experience in mechanical and hydraulic field and their research by on site application, customer communication, Dahua launches its new crushing equipment for aggregates processing to create value for the customers.

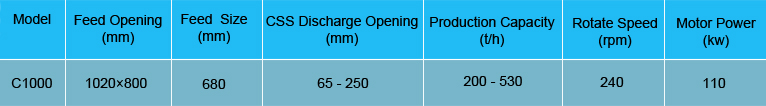

C1000 Series Jaw Crusher

1. Technical Parameters

2. Performance Highlights (Specially Designed for Limestone)

♦Larger Production Capacity

With outstanding movement characteristic and unique chamber shape, C1000 Jaw Crusher guarantees larger production capacity than the same model jaw crusher.

The production capacity has increased around 7%, the rotating speed has increased to 240 rpm, increased 9% by the optimized design of adjustable rotation angle. At the conditions of the same discharging opening, C1000 has larger throughout.

♦Energy – Saving

Energy consumption can save up to 10%, by enlarge the diameter of belt pulley and increase the rotational inertia.

♦Stability

Enlarge the diameter of the bearing and increase the strength of the main shaft to improve the machine safety stability.

Easy Installation and Maintenance: The spring rod has reduced from 2 to 1 and the unilateral side liner has reduced from 3 to 2, which dramatically reduces the installation workload and make the machine easy to maintenance.

The fixed jaw plate and movable jaw plate are universal parts. By turning the jaw plate upside down, the jaw plate could be used for 4 times longer than the normal jaw plate, which increases the material utilization rate and reduces the spare parts quantities. To make the machine much more cost-effective and easy to maintenance.

♦Stable Performance

The spring structure is replaced by movable jaw plate tension spring that makes the machine has large loading capacity and stable performance.

♦Fast Adjustment

The discharge opening could be adjusted by hydraulic jack that makes the adjustment faster and easier.

If you are interested in them, please contact us:

Tel: 86-379-62669978

E-mail: [email protected], [email protected]