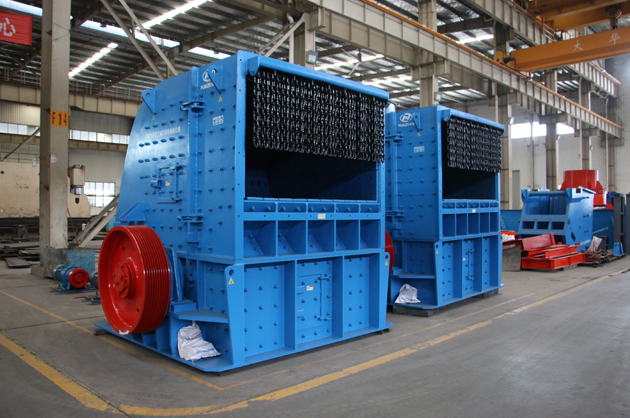

Luoyang Dahua offers a wide selection of Impact Crushers for processing soft materials like coal or hard and abrasive materials like dolomite or sandstone.

Typical applications are the crushing of limestone, dolomite, gypsum and phosphates as well as the crushing of demolition waste and asphalt. The impact crusher allows the use in stationary as well as in semi-mobile and mobile plants – mobile impact crusher. Impact crushers from Luoyang Dahua are characterized by a high crushing ratio, low energy cost, strict quality control of products.

How Impact Crushers Work

The material is fed through the feed opening into the crusher and is hit by the blow bars fixed in the rotor. Here the material is crushed by the large kinetic energy of the blow bars hitting the rocks. The material is crushed at the natural fracture surfaces and thrown against the first or second impact plate, where it is crushed further. From here, the material is deflected to the impact circle of the rotor. This process is repeated until the crushed material passes through the adjustable gap between the impact apron and rotor and is finally discharged through the bottom of the machine.

Luoyang Dahua Impact Crusher Type

The impact crusher is mainly divided into PFQ impact crusher, ISP impact crusher, and BP series impact crusher.

PFQ impact crusher has eight models to choose from. The maximum size of feed opening is 150-700mm, the output is 30-40mm, and the production capacity is 50-1000t/h. Common models are PFQ-1315, PFQ-1320, and PFQ-1520.

ISP impact crusher feed grain size is not more than 150mm, the capacity is 50-100t/h. There are three models of ISP1005, ISP1008 and ISP1010. This series has outstanding impacting performance and good grain shape.

BP series impact crushers are designed for different applications to improve the performance and capacity of the crusher. The maximum feed size is 600-1400mm, and the production capacity is 55-1100t/h.