Jaw crusher is generally used in the first process of stone crushing, which is used to break large pieces of stone into small pieces. Do you know the structural components of a jaw crusher? How does a jaw crusher work? What are the parameters of jaw crusher? Today Luoyang Dahua will give you a general introduction.

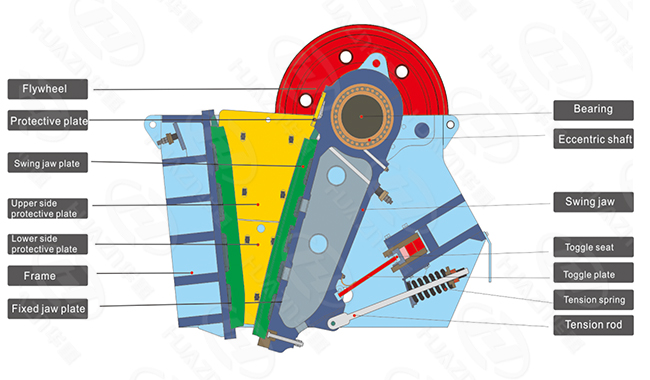

I. Structural components of jaw crusher:

Jaw crusher is mainly composed of frame, eccentric shaft, fixed jaw plate, movable jaw plate, guard plate, tooth plate, adjusting seat, top rod and pull rod. As shown in the picture below:

II. Working principle of jaw crusher:

The working part of jaw crusher is two jaw plates: one is fixed jaw plate, fixed vertically on the front wall of the body. The other is the movable jaw plate, which is inclined and forms the crushing chamber with the fixed jaw plate. The movable jaw plate does periodic reciprocating motion around the suspension shaft against the fixed jaw plate, sometimes approaching and sometimes leaving. Near the fixed jaw plate, the ore between the two jaw plates is crushed by the combined action of crushing, splitting and bending. When the movable jaw plate leaves the fixed jaw plate, the crushed ore is discharged through the discharge port of the jaw crusher under the action of gravity.

III. Parameters of jaw crusher:

The main technical parameters of jaw crusher include feed opening size, discharge opening size, processing capacity and power, etc. The production capacity of the jaw crusher is related to the model of the equipment and the size of the discharge opening. Generally speaking, the larger the discharge opening is, the greater the production capacity is.

| Model | Feed Opening Size(mm) | Max. Feed Size(mm) | Discharge Opening Size(mm)/Capacity(t/h) | Power(kw) | ||||||||||||||

| 40 | 50 | 60 | 70 | 80 | 90 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 | 300 | ||||

| JC80 | 800×510 | 430 | 50 | 55 | 80 | 90 | 110 | 120 | 135 | 170 | 200 | 240 | 75 | |||||

| 70 | 85 | 100 | 125 | 145 | 170 | 185 | 240 | 280 | 330 | |||||||||

| JC90 | 910×630 | 530 | 90 | 105 | 115 | 135 | 150 | 170 | 200 | 230 | 270 | 90 | ||||||

| 130 | 140 | 165 | 185 | 200 | 240 | 270 | 300 | 345 | ||||||||||

| JC100 | 1000×760 | 640 | 120 | 140 | 155 | 175 | 210 | 250 | 300 | 340 | 110 | |||||||

| 170 | 195 | 215 | 255 | 300 | 350 | 420 | 480 | |||||||||||

| JC110 | 1100×850 | 720 | 180 | 200 | 220 | 245 | 300 | 350 | 400 | 460 | 132 | |||||||

| 240 | 265 | 295 | 320 | 385 | 455 | 520 | 590 | |||||||||||

| JC125 | 1250×950 | 810 | 270 | 325 | 385 | 445 | 500 | 560 | 620 | 160 | ||||||||

| 360 | 430 | 505 | 580 | 650 | 725 | 800 | ||||||||||||

| JC140 | 1400×1070 | 910 | 360 | 425 | 490 | 555 | 625 | 690 | 725 | 200 | ||||||||

| 470 | 555 | 640 | 725 | 815 | 900 | 985 | ||||||||||||

| JC160 | 1600×1200 | 1020 | 490 | 560 | 635 | 710 | 780 | 855 | 930 | 250 | ||||||||

| 640 | 730 | 825 | 920 | 1010 | 1105 | 1200 | ||||||||||||

| JC210 | 2100×1600 | 1360 | 800 | 900 | 1000 | 1100 | 1200 | 1300 | 450 | |||||||||

| 880 | 1005 | 1125 | 1225 | 1375 | 1500 | |||||||||||||

IV. The influence factors of the production capacity of jaw crusher:

1, Material hardness

2, Material composition

3, Material viscosity

4, Material humidity

5, Material fineness after breaking

Luoyang Dahua is one of the TOP crusher machine manufacturers in China. The hot products are jaw crusher, cone crusher, impact crusher, sand making machine, and mobile crusher plant. If you don’t know how to choose the crusher machine, please contact the Online Service to get latest quotation.