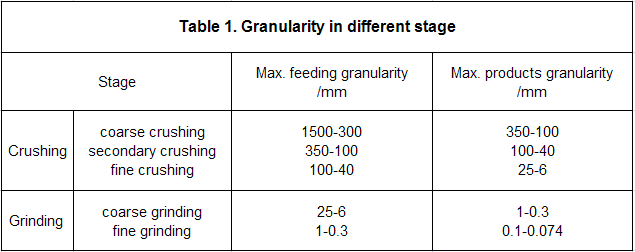

The ore and flux that transport to the nonferrous metallurgy factory, the maximum ore size is up to 1000mm. It is impossible to use one machine to crush the materials one time into the required granularity for each smelt procedure under the current technology. We must use a number of different types of crusher and grinder to complete crushing. Each stage only completes one part of the tasks in the whole crushing process. The "stage" in the smelting plant is divided according to the feed materials and products granularity, shown in the table 1. The stages in the table show the general situation.

After crushing, the grain size becomes small, the value for the original granularity and the crushed granularity is called crushing ratio (at crushing stage calls crushing ratio, at grinding stage calls grinding ratio). Crushing ratio shows the decreased multiple of crushed ore granularity in letter S.

Stage crushing and crushing ratio: Stage crushing ratio (or called partial crushing ratio) refers to the crushing ratio at different crushing stages. The raw materials granularity before crushing compare to the final products granularity after several crushing stag is called total crushing ratio. Total crushing ratio equals to continued product of each stage crushing ratio, i.e. S=S1×S2×S3×….×Sn (S — total crushing ratio, S1、S2、S3、……、Sn — first, second, third … n stage's crushing ratio)