PLS Series Sand Making Machine

Max. Feed Size: 30-60(mm)Processing Capacity: 24-715(t/h)

Application Fields: water conservancy, refractory material, construction, highway, railway, etc.

Applied Materials: granite, basalt, greenstone, sandstone.

Tel.: +86-379-62669977 E-Mail: [email protected]

Overview

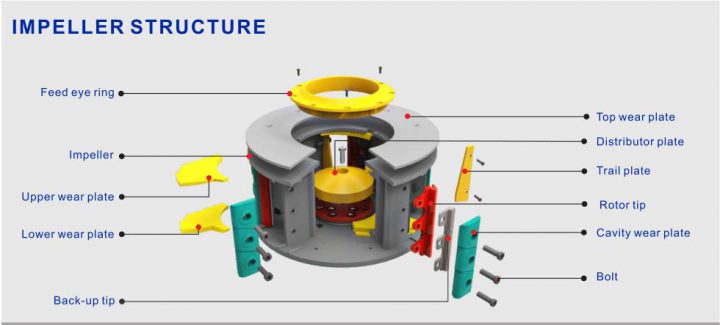

PLS Series Vertical Shaft Impact Crushers are our self-developed products with principle of material impacts or material-metal imapacts. This type has passed the identification of national new product since 1991, and was awarded National New Product in 1992. It perfectly combines the unique rotor structure design, wear-resisting material technology, speed optimization and hydraulic design.

Product Features

1.Unique design of rotor and cavity, high operational capacity and yield, good shape for high bulk density.

2.Multipurpose and flexible application — owning varieties of cavity types to switch from “stone-stone” to “stone-steel”

3.Specific transmission structure to ensure high speed and smooth running.

4.Specific structure and material of wearable parts increases its using life and reduce the operating cost.

5.Automatic hydraulic device and lubrication, anti-vibration, temperature control and timing sensing device together guarantee safe operation and easy control.

6.Low-energy consumption and long-life service of quick-wear parts, which adopt the best wear-resistant material at home and abroad.

Working Principle

Stone Beat Stone: The materials fall vertically and uniformly from the top of the machine. One part of them enter into the revolving impeller at high speed through the distributor and feed pipe, and are shoot out from the discharge outlet of impeller by the action of the high-speed centrifugal force. Then at high speed they are smashed with another part of the materials that have been distributed around impeller through the distributor. After smashing each other the materials shall form whirlpool and impact many times caused by striking and attrition in the impeller and crushing chamber.

Stone Beat Iron: The materials fall vertically and uniformly from the top of the machine, and enter into the revolving impeller at high speed through the feed pipe. Then they are shot out from the discharge outlets of impeller by the action of the high-speed centrifugal force, and at high speed strike and crush with impact plate around the impeller.

Technical Parameters

Technical Parameter

| Model | Working Mode | Max. Feed Size (mm) |

Impeller Diameter (mm) |

Impeller Speed (r/min) |

Power (kW) |

Capacity (t/h) |

| PLS-550 | Sand Making | 30 | 570 | 2290 | 30 | 16-20 |

| 37 | 20-26 | |||||

| 45 | 24-32 | |||||

| PLS-700 | Sand Making | 35 | 720 | 1830 | 55 | 30-38 |

| 75 | 40-52 | |||||

| 90 | 50-65 | |||||

| PLS-850Ⅱ | Sand Making | 50 | 880 | 1570 | 2×90 | 95-125 |

| 2×110 | 120-160 | |||||

| 2×132 | 150-195 | |||||

| Fine Crushing | 5 | 880 | 1795 | 2×110 | 90-120 | |

| 2×132 | 120-150 | |||||

| PLS-1000Ⅱ | Sand Making | 60 | 990 | 1365 | 2×160 | 200-260 |

| 2×200 | 250-325 | |||||

| 2×220 | 275-360 | |||||

| 2×250 | 350-585 | |||||

| Fine Crushing | 5 | 990 | 1545 | 2×160 | 150-180 | |

| 2×220 | 225-250 | |||||

| PLS-1200Ⅱ | Sand Making | 60 | 1110 | 1220 | 2×250 | 320-410 |

| 2×280 | 375-490 | |||||

| 2×315 | 450-715 | |||||

| Fine Crushing | 5 | 1110 | 1400 | 2×250 | 260-300 | |

| 2×280 | 300-350 |

Customer Cases