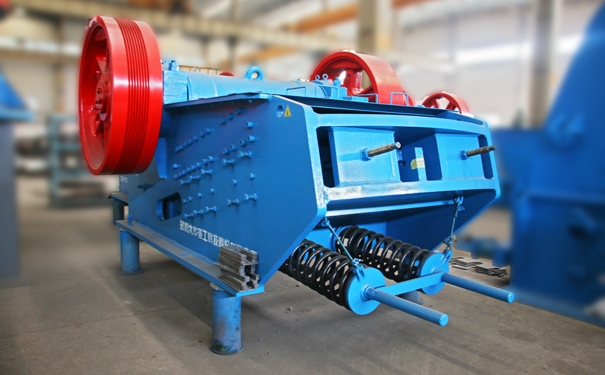

PEY series hydraulic protection jaw crusher is a single cylinder hydraulic compound pendulum jaw crusher developed by Luoyang Dahua. This machine can be used for coarse and medium crushing of steel slag. The PEY series jaw crusher comes with a hydraulic station and PCL automatic control system. It has a high degree of automation. The single hydraulic cylinder supported by the hydraulic station can adjust the size of the discharge port and unload the unbreakable objects. It is reliable and automatic. Unbreakable materials are discharged, which effectively solves the problem of "steel jam" in the steel slag crushing. After iron discharge, it can automatically reset, which can realize continuous production without shutdown, which makes the operation more convenient, greatly reduces the parking time, and effectively improves the work efficiency.

There are many factors that affect the work of the jaw crusher, but the impact of overload problems is more common. Because the compressive strength of the same material is not uniform, and some particles have a relatively large compressive strength, the jaw crusher will overload during the working process, and the working load of the jaw crusher has very large fluctuations. The peak load of its work is usually about 3 to 4 times the normal working state. In actual operation, non-crushed objects are often encountered and enter the crushing cavity, causing the jaw crusher to be severely overloaded instantly. If there is no safe and reliable overload protection device, the crusher will malfunction, and the equipment parts will be damaged in severe cases. Therefore, in order to avoid overload, the jaw crusher must have a good self-protection system. When it is overloaded, the parts of the jaw crusher not only are not damaged, but also can quickly resume normal work.

The hydraulic protection device of the jaw crusher plays the role of overload and iron, and effectively discharges the unbreakable objects. The jaw crusher is composed of a movable jaw, a fixed jaw and an eccentric wheel. The fixed jaw does not move during work. The eccentric wheel rotates under the drive of the electric motor and drives the movable jaw to make a compound swing motion, thereby breaking the movable jaw and the fixed jaw Of materials. The piston rod of the hydraulic cylinder is connected to the lower part of the movable jaw through a hinge. The left and right positions of the piston rod determine the size of the orifice below the crusher. When the crusher is overloaded, the piston and piston rod of the hydraulic cylinder quickly move to the right to increase the ore discharge port between the movable jaw and the fixed jaw, the overloaded material is automatically discharged from the ore discharge port by its own weight. When the overload phenomenon is eliminated, the oil pump supplies oil to the right cavity of the hydraulic cylinder, and the piston and piston rod are under pressure Under the action of oil, it moves to the left and resets to the limit position. The orifice between the movable and fixed jaws returns to its original size and the jaw crusher resumes normal operation. Next, let's look at the working process of the hydraulic protection device.

1. Normal work

The pressure of the crusher thrust plate acting on the working hydraulic cylinder is less than the hydraulic cylinder thrust, the action valve is at the upper limit position, the thrust plate does not move, and the crusher normally crushes the material.

2. Overload protection

When the crushing cavity of the jaw crusher enters a non-crushing object, the crushing force is increases. At this time, the pressure of the thrust plate of the jaw crusher on the working hydraulic cylinder is greater than the thrust provided by the hydraulic cylinder. The high pressure oil chamber of the working hydraulic cylinder When the oil pressure rises instantaneously, the throttle valve activates the action valve, and the system (hydraulic cylinder) drains oil, limiting the maximum thrust of the thrust plate (the maximum crushing force) to protect the machine.

3. Troubleshoot

After the non-crushed material enters the crushing chamber, due to the maximum thrust provided by the working hydraulic cylinder, the piston moves to the right and retracts, correspondingly the crusher discharge port increases, and the non-crushed material gradually descends due to the engagement of the crushing motor jaw Movement and finally discharged from the mine discharge port, automatically excluding non-crushed objects in the crushing cavity. If the "product" produced by the non-crushed product in the crushing chamber is unqualified, it can be rejected by the auxiliary device.

4. Automatic recovery

When the non-crushed material is automatically removed, the piston is in the retracted position. Due to the reduction of the crushing force, the action valve returns its spool to the upper limit position without the instantaneous high pressure of the upper chamber, and no longer drains the system; The fuel injection pump pumps oil to the system with the maximum pump oil volume under the action of the oil pressure adjustment device, until the working hydraulic cylinder piston moves to the left to the limit position. At this point, the crusher returned to normal working condition.