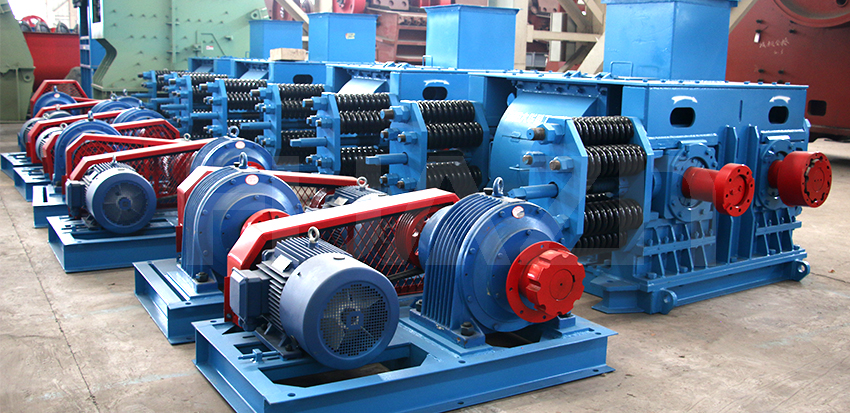

The roll crusher is suitable for crushing brittle bulk materials in various industries, including cement, chemical industry, electric power, mining, metallurgy, building materials, refractory materials, and coal mining. It is specifically designed for medium crushing of materials with a compressive strength ≤160MPa. Additionally, it has a large feeding size and an adjustable discharging size. What factors will influence the production capacity of roll crusher?

- Material hardness. The more hard the material is, the more difficult to crush and more serious abrasion for the machine.

- Material humidity. The more water is contained, the easier to adhere to the machine and block the discharge transportation, thus reducing the crushing capacity.

- Crushed material fineness. The more fine the crushed material, the less crushing capacity.

- Material composition. The more fine powder contained in the material, the easier to adhere to influence the transportation. Take pre-screen for more fine powder material.

- Wear resistance of crushing machine. The better wear resistance the crushing parts (hammer head, jaw plate) are, the larger crushing capacity.