Project description: The project is the use of local sand-coated soil, mud stone, and limestone mixture to produce high-quality concrete with mechanical sand. In order to achieve stable, reliable, continuous and efficient production, Luoyang Dahua Heavy Industry provides customers with customized high-quality sand making machine production line solutions according to the project site planning and the actual production needs of customers. The whole production line includes crushing, sand making, sand washing and other processes to achieve integrated production mode, and based on the advantages of the site to effectively reduce the cost of the production line and improve the output of finished products.

Raw materials: sand-coated soil, mud-coated stone, limestone mixture

Production capacity: 400-500 t/h

Crusher equipment: ZSW vibrating feeder, JC jaw crusher, GPY cone crusher, PLS sand making machine, YK vibrating screen, XL spiral classifier, and bucket wheel sand washing machine.

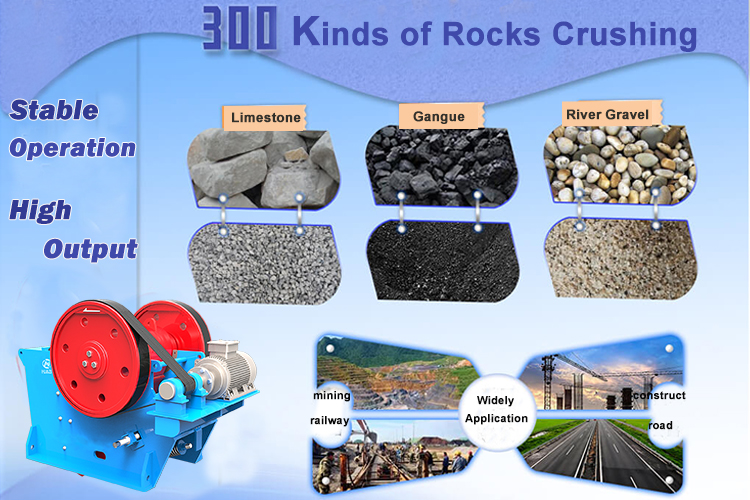

✤ Luoyang Dahua jaw crusher advantages:

- Reasonable structure, anti-wear parts.

- Deep cavity crushing, high yield and energy saving.

- Simple operation and easy maintenance.

- The equipment has high strength and good carrying capacity.

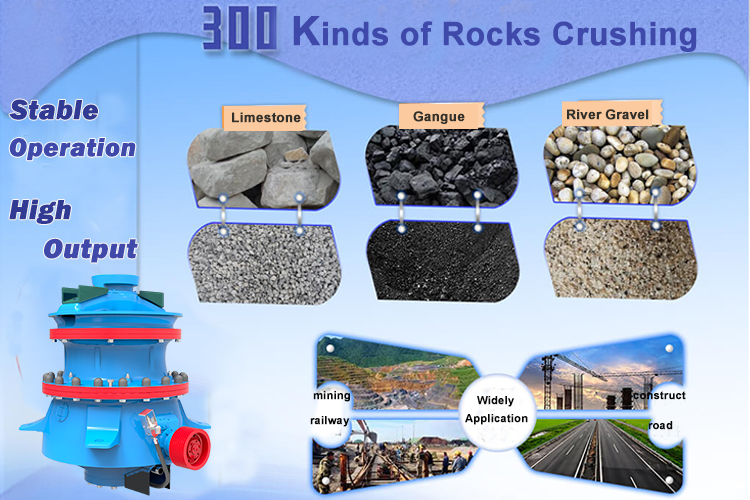

✤ Luoyang Dahua cone crusher advantages:

- Secondary crushing, large output, for varieties of stone crushing.

- Laminating crushing principle, good finished particle size.

- Simple structure compares with multi-cylinder cone crusher, easy operation, and low maintenance cost.

✤ Luoyang Dahua sand making machine advantages:

- A variety of crushing standards – “stone beat stone”, “stone beat iron”.

- The finished product has excellent grain shape, and the stone output is increased by 30%.

- Environmental protection, energy saving, less dust, and low noise.