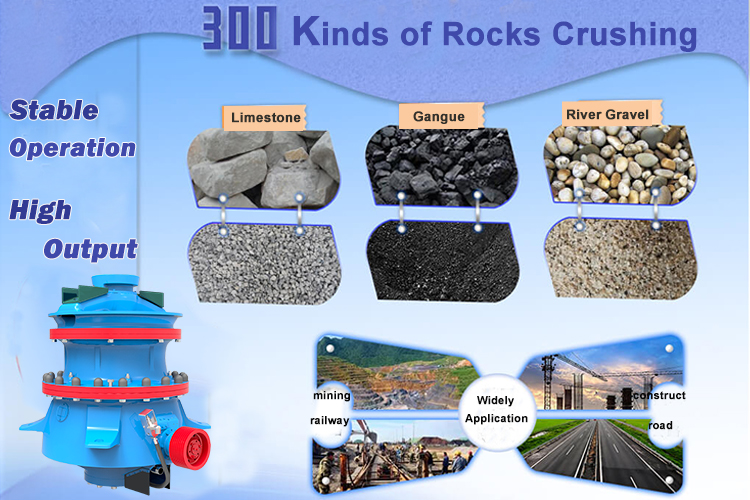

Cone crusher is suitable for medium and fine crushing of all kinds of ores and rocks with a hardness of f≤5-16. It is a medium and fine crushing equipment widely used in various major industries, such as metallurgy, construction, road construction, mining, quarrying, and other fields. Cone crushers with various cavity types can be selected, allowing for convenient adjustment of the discharge opening. The type of crushing chamber is determined by the ore being used, demonstrating good adaptability to medium and fine crushed ores and rocks.

With the continuous development of mining technology, cone crusher is constantly upgrades and improved. The cone crusher on the market is divided into four categories: multi-cylinder hydraulic cone crusher, single-cylinder hydraulic cone crusher, compound cone crusher and spring cone crusher. These types of cone crushers have the characteristics of large crushing force, high efficiency, large processing capacity, low operation cost, convenient adjustment, economic use and so on.

The main cone crusher of Dahua Heavy Industry is HPY series multi-cylinder cone crusher and GPY series single-cylinder cone crusher, what is the difference between these two cone crushers?

1、Different crushing effect

Cone crusher is through the lamination crushing to achieve the original crushing processing of materials. Single cylinder cone crusher has good medium crushing effect, and large passing capacity. Multi-cylinder cone crusher fine crushing effect is good, the fine material content is high. Single cylinder and multi-cylinder cone crushers are high-performance crushers, compared with single cylinder cone crusher, multi-cylinder cone crusher is more dominant in structural performance maintenance.

2、Production capacity

Single-cylinder cone crusher has large through capacity for soft ore and weathered ore. When break hard rocks, the difference between these two cone crushers are greater.

3、Maintenance

The single cylinder cone crusher has simple structure, low failure rate, low production cost, and more stable operation.

All parts of the multi-cylinder cone crusher can be disassembled and maintained from the top or side, and the daily replacement is convenient.

In the process of using cone crusher, it is necessary to choose the right type and model according to the actual work needs to make full use of its advantages. The discharge particle size of the cone crusher depends on the hardness of the ore and the setting of the crusher, and a reasonable setting can make the cone crusher achieve the best working state.