The 1000 tph stone aggregates production line is a kind of equipment system to break large stones into small particles, mainly used in construction, road and mineral resources development and other fields. When setting up a production line, there are many factors need to be considered, including raw material source, finished aggregate demand, equipment selection and configuration. The following will introduce in detail the configuration of 1000 tph stone aggregate production line and the price.

I. Raw material treatment

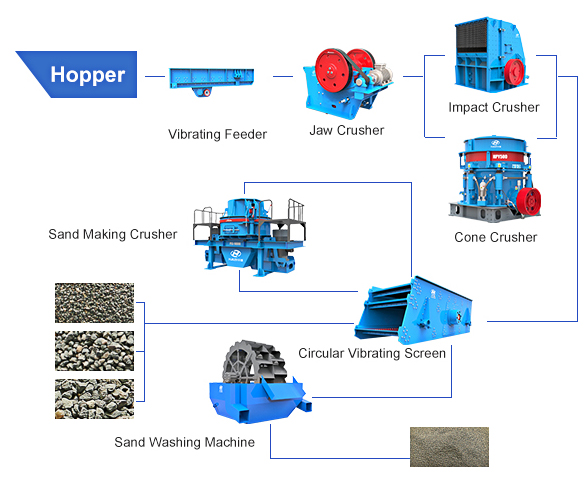

First, large blocks of stone are transported to the primary crusher (jaw crusher) for initial crushing. This can reduce the size of the raw material and facilitate subsequent processing and treatment.

II. Main equipment

Jaw crusher: Used for primary crushing, breaking large pieces of stone into smaller rubble.

Impact crusher: Used for intermediate crushing, further refining the gravel to obtain the required fine aggregate.

Cone crusher: Used for fine crushing to obtain finer aggregate.

III. Screening equipment

The vibrating screen is used to screen the crushed stone, and the finished aggregate of different specifications is obtained. The vibrating screen can be selected and configured according to the requirements to obtain the required finished aggregate.

IV. Sand washing equipment

If it is necessary to further improve the quality of the finished aggregate, stone sand washing machine can be added. The stone sand washing machine can wash away the soil and impurities in the gravel and improve the quality and cleanliness of the finished aggregate.

V. Conveying equipment

The conveyor equipment is used to transport raw materials and finished aggregates in the production line. Conveyor equipment can choose belt conveyor or vibration conveyor according to the actual needs for selection and configuration.

VI. Vibrating feeder

Vibrating feeder can evenly feed raw materials into the crusher to ensure the stable operation of the production line. Vibrating feeder can be selected and configured according to actual needs.

The price of a full set of equipment

The price of a full set of equipment for 1000 tph stone aggregate production line is about $ 380000 – $ 570000. The specific price may vary due to market fluctuations, equipment configuration and equipment selection. It is recommended that when selecting the equipment, the selection and configuration should be carried out according to the actual needs to ensure that the finished aggregate meets the requirements and reduces the cost as much as possible.

To sum up, the construction of 1000 tph stone production line needs to consider a number of factors, including raw material source, finished aggregate demand, equipment selection and configuration. The detail configuration of the production line should be carried out according to the actual needs and customer investment.

Luoyang Dahua has 60+ years experience in manufacturing mining crusher machine, the hot products are jaw crusher, cone crusher, impact crusher, sand making machine, and mobile crusher. From machine selection to site installation, and operator training, the professional engineer will take in charge of the whole process. Please contact us at any time to get latest quotation.