The full set of sand and stone production line equipment is a combination of various equipment specializing in the production of construction sand and stone. The production capacity ranges from 30 t/h to 1500 t/h. How to select the place to build a stone sand production line?

Aggregates quarry site selection should follow the principles as below:

① The concrete should meet the quality requirements for aggregates, and its storage volume should be designed to accommodate each grading while also allowing for necessary surplus.

② The quarry site, especially the main site, should possess certain features such as spacious grounds, suitable elevation, ample storage capacity, excellent quality materials, and extended mining seasons. The main and auxiliary sites should be able to support each other during both low and peak seasons.

③ Should choose the quarry site that has high mining rate, relatively close to natural grading and design grading, small amount of artificial aggregate adjusted gradation.

④ Around quarry site have sufficient reture and stocking yard, and less occupying farmland.

⑤ Should choose the quarry site that has small mining preparation work and convenient construction.

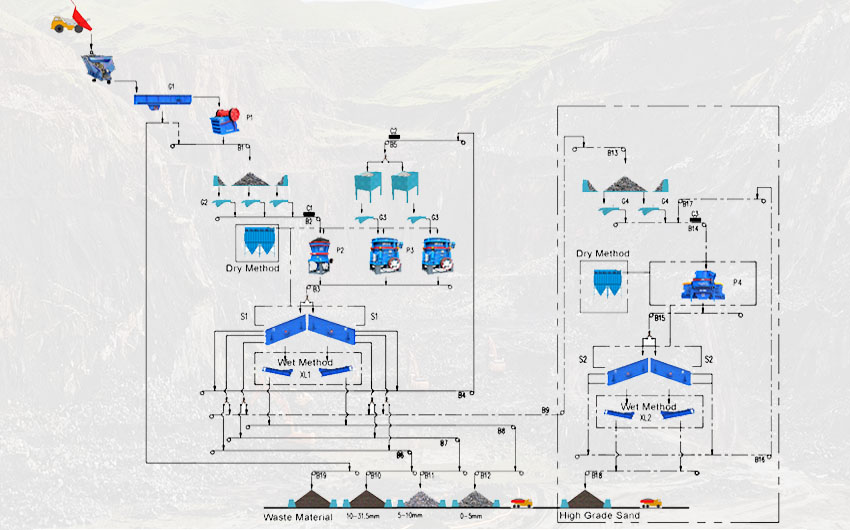

Stone sand production line process

The production process of sand making machine is mainly as: (stock bin) – feeder – jaw crusher – impact crusher – vibrating screen – (finished products). Among them use conveyor to connect.

Firstly, stones are evenly sent into coarse crushing machine for primary crushing, and then transport to the impact crusher for further crushing by belt conveyor. The fine crushed materials are separated into different size of stone by vibrating screen. The stone that did not meet the requirements of grain size returns into the impact crusher to break again.

Stones are sent to the jaw crusher by vibrating feeder for coarse crushing, the crushed materials are transfered into the sand making machine for further broken, after the fine crushing, the materials to be delivered to vibrating screen for screening. The qualified materials are transfered to sand washer, and then to be discharged as the finished products. Materials do not meet the product particle size requirements return from the vibrating screen to the sand making machine, forming closed-circuit circulation.

The finished products granularity can be grading according to the customer needs. If choose dry process production technology, can be equipped with thick powder separator and dust removal equipment.

Luoyang Dahua Heavy Industry is a high-tech enterprise with research & development production, sales, and service. The mobile crushing station has been successfully applied in domestic and foreign mine crushing projects. The company has a professional R & D team, a strong after-sales team, from the equipment selection, site inspection, equipment manufacturing, installation, commissioning, delivery and other aspects for your service.