The hardness of silica is about 6.5~7, which is one of the harder minerals. Silica has excellent physical and chemical properties, high stability and is not easy to damage. Therefore, silica has a wide range of applications in industry, construction, electronics and other fields. In this text, we mainly introduce the silica rock crusher machine. Choose the appropriate silica crusher equipment, optimize the debris effect, and lay a good foundation for subsequent processing.

Silica rock crusher: jaw crusher (primary crusher)

According to the specifications of raw materials, the breaking of small stones is easier, so it is recommended to break in stages. The jaw crusher is used to break silica rock into appropriate size, and then for secondary crushing, which can speed up the crushing efficiency.

Basically, the primary crushing equipment is a jaw crusher. The primary crushing of mineral processing line is usually completed by it. There are small jaw crusher, JC series large jaw crusher, and European jaw crusher, etc., users can choose according to their needs.

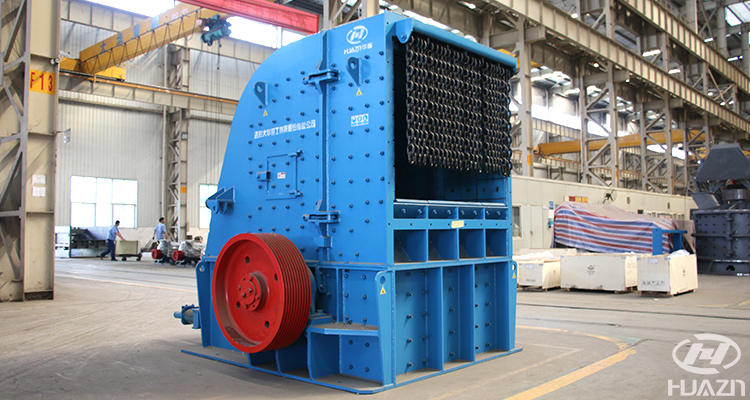

Silica rock crusher: impact crusher (medium crushing in small and medium production lines)

After the primary crushing is completed, secondary crushing treatment is required. For large-scale production lines, impact crushers can be considered. Then combined with sand washing equipment, it can also process high-quality silica sand.

Impact crusher uses the impacting principle, the impact plate wear is relatively slow, this needs the regular maintenance and replacement so as not to affect the stable work of the crusher.

Silica crusher: cone crusher (large building materials production line and mineral processing production line)

For the crushing treatment of the beneficiation production line, the more commonly used secondary crushing equipment is the cone crusher. Compared with the impact crusher, its processing capacity is smaller, working efficiency is higher, and more models are available. There are full hydraulic, multi-cylinder hydraulic and single cylinder hydraulic cone crushers, which can be selected according to the user’s work needs.

Moreover, cone crusher is more suitable for crushing materials with higher hardness and the operation and maintenance cost is more cost-effective. Therefore, if you are dealing with silica beneficiation, cone crusher is relatively more suitable. Of course, which device should be chosen depends on the specific needs of the user.

In general, the purchase of appropriate equipment, first look at the quality, followed by the price, the third look at after-sales service. Choose Luoyang Dahua: one-stop purchase service, regardless of any problems encountered in the selection or actual production, you can contact us at any time. The professional technician will reply within 2 hours.