Silicon carbide, also known as carborundum or refractory sand, is mainly used in functional ceramics, high-grade refractory materials, abrasives and metallurgical industries. The classification of micro-powder for silicon carbide is subject to special requirements due to its predominant use in the abrasive industry. Considering the high hardness and difficulty in grinding of silicon carbide, Luoyang Dahua Heavy Industry has designed a crushing production line that is reasonable, reliable in quality, stable in performance, easy to operate and maintain, and free from dust pollution.

◊◊ Silicon carbide crushing production line composition

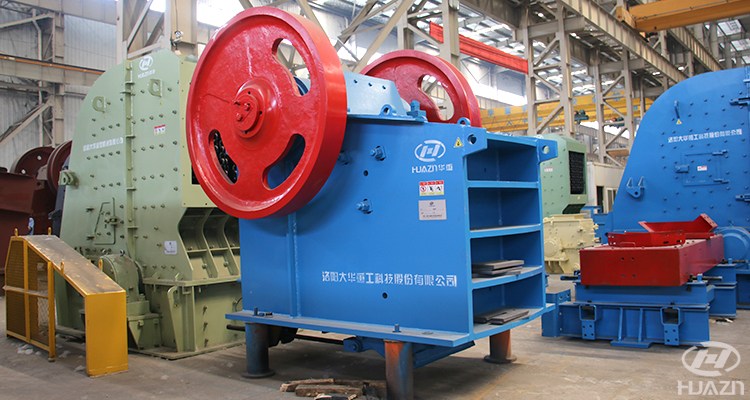

The complete configuration of the silicon carbide production line includes a jaw crusher, a sand making machine, a vibration feeder, a bucket elevator, a storage bin, a pulse dust removal system, and an electrical control system, etc. The following is the 600 tph silicon carbide crushing production line of Luoyang Dahua Heavy Industry.

◊◊ DHKS Jaw Crusher

DHKS jaw crusher is the small and medium-sized crusher equipment, the output is 7-23 tons per hour, processing particle size is less than 210mm, discharge particle size is 20-80mm, the motor power is 15kw.

◊◊ PLS Sand Making Machine

PLS sand making machine production capacity is 16 – 1100 t/h. It has a high sand production rate and maintains the integrity of grain type. The protective plate, made from high manganese steel, can be flipped and used twice, reducing costs for users. Additionally, the hydraulic open cover design facilitates daily repair and maintenance.