The rod mill is a widely used equipment in the steel, metallurgy, building materials, chemical, and other industries. It is capable of grinding various hard materials such as ores, cement, glass, and ceramics, etc. In the metallurgy industry of iron and steel, the rod mill is utilized for processing metal materials such as iron bars and rebar. In the building materials industry, the rod mill is employed to process cement and other materials in order to manufacture building materials. In the chemical industry, the rod mill is utilized for processing chemical substances that contain particulate matter.

Rod mill working principle

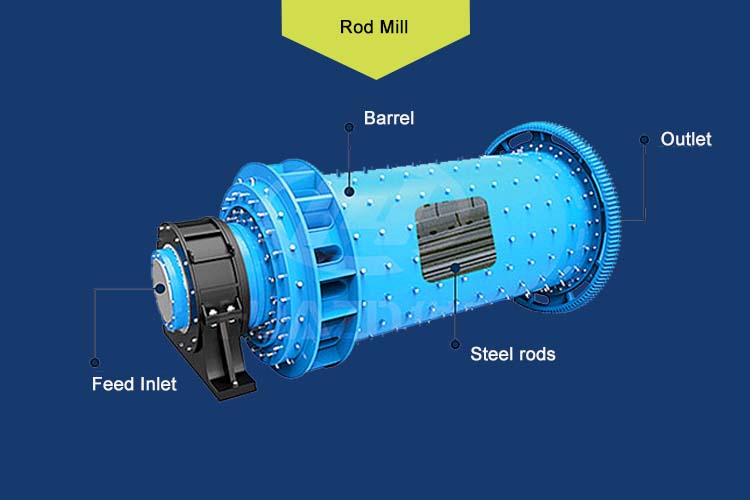

The rod mill is primarily comprised of a motor, pulley, reducer, gear rack, grinding rod, and other essential components. Its working principle is to send hard materials into the grinding rod where they undergo wear and friction processes to achieve finer particle sizes for effective grinding purposes.

Rod mill features

- It can be utilized for grinding a diverse range of tough materials, offering extensive applicability.

- The grinding efficiency is high, enabling rapid processing of the desired particle size.

- The equipment structure is characterized by simplicity, user-friendliness, and ease of maintenance.

- The implementation of automatic control can be tailored to specific requirements in order to enhance production efficiency.

Rod mill application

In summary, the rod mill is a mechanical equipment widely utilized in various industries. Its primary function is to efficiently grind hard materials into the required particle size, offering advantages such as high efficiency and convenience. For industries requiring processing of tough substances, the rod mill is an indispensable equipment; however, attention should also be paid to factors like investment cost and noise impact.