Because the cone crusher and the impact crusher belong to the fine crushing equipment, the customer will have difficulty in choosing. In fact, there are many different in various aspects between these two crushers. Today, Luoyang Dahua will talk in detail about what is the difference between cone crusher and impact crusher when choosing for fine crushing.

1、Different types of broken stone

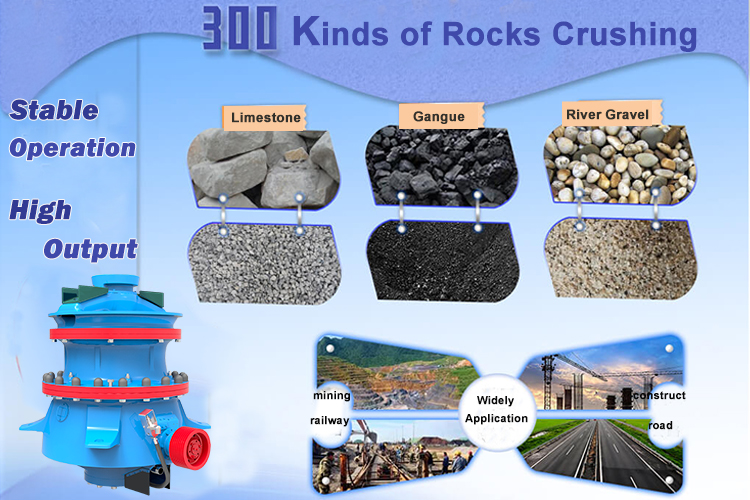

- The cone crusher mainly breaks stone materials with greater hardness, such as granite, basalt, tuff, river pebbles and so on.

- Impact crusher is used to break small hardness and brittle materials, such as limestone, calcite and so on.

2、Different working principles

- The impact crusher uses impact crushing, and the material is repeatedly crushed between the plate hammer and the impact plate, and finally discharged from the discharge port.

- The cone crusher adopts the combination of extrusion, shearing and grinding, and concave constantly moves to the mantle to squeeze the materials to achieve crushing.

- Compared with the working principle of the two crushers, the cone crusher is higher in crushing efficiency, and the impact crusher is better in crushing effect.

3、Different discharge grain type

- From the finished particle shape, because the impact crusher relies on the principle of impact crushing, the finished particle shape is good with less powder.

- The cone crusher relies on extruded materials for lamination and crushing, so the content of finished needles is more.

- In the actual production process, the cone crusher is used in the beneficiation process, and the impact crusher is used in the building materials and construction projects.

4、Different wear resistance

- The impact crusher has more vulnerable parts, such as the hammer, the impact plate and other parts, which need to be replaced frequently, so the loss and depreciation of the equipment is faster, and the operation and maintenance cost is higher in the later period.

- The wearing parts of the cone crusher have a long life, and there is no need to regularly replace the parts, so the loss and depreciation of the equipment are slower, and the operation and maintenance cost is lower in the later period.

5、Different production capacity

- PFQ impact crusher processing capacity is 50-1200t /h, HPY multi-cylinder hydraulic cone crusher processing capacity is 60-2500t /h.

- Compared with the impact crusher, the cone crusher has the characteristics of low energy consumption, large output and stable production, so the cone crusher is often used for large-scale high-yield production line operations.

6、Different price

- The price of the cone crusher is more expensive than the impact crusher, but its wearing parts have a longer life, avoiding the trouble of frequent replacement parts, and the maintenance cost for wearing parts replacement is also lower. In the long run, cone crusher is more cost-effective than the impact crusher.

The above is the difference between cone crusher and impact crusher, in actual production, the specific type of equipment to choose, we also need to consider according to different materials, input and output particle size, production capacity and other aspects, and finally select more suitable equipment.

Luoyang Dahua has 60+ years experience in manufacturing mining crusher machine, the hot products are jaw crusher, cone crusher, impact crusher, sand making machine, and mobile crusher. From machine selection to site installation, and operator training, the professional engineer will take in charge of the whole process. Please contact us at any time to get latest quotation.