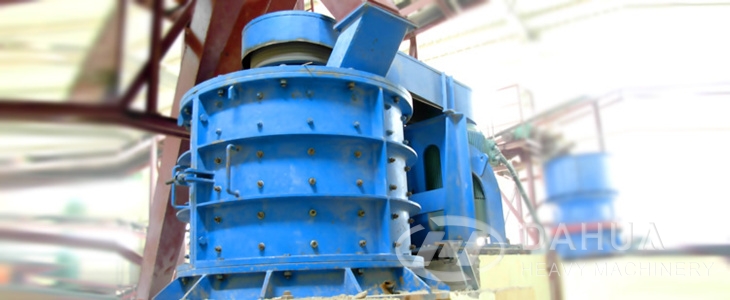

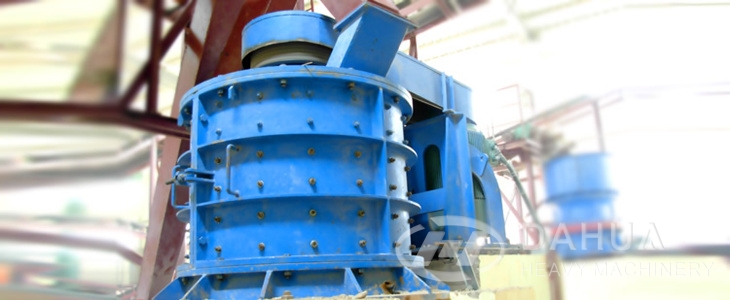

During cone crusher crushing stones, it makes regular movement. Since the crushing cone and the eccentric sleeve are not on their central line when rotating, which generating inertia force and inertia movement compared with relative fixed hanging point. Both of the force jointly together applied on the frame body as a periodical moving load that causes the shaking of the frame body and the deflection of the eccentric sleeve. Though some kind of balance is adopted, actually due to the tolerance generates during product production and machine installation, the crusher main shaft edge usually has contact with the eccentric sleeve that may lead to flaws or even broken of the shaft and the flaws on the taped sleeve, which may cause crusher breakdown.

Through the analysis of above issue, we come up with solutions. The reason of flaw generation is that the main shaft is forced to the thin edge of the eccentric sleeve when the cone crusher is running without loading. Then the thicker edge of the eccentric sleeve left some space. On the contrary, when the shaft is forced to the thicker edge, then some space is left on the thin edge. During the inspection procedure, we usually find flaws on the thicker edge of the eccentric sleeve, which caused by improper installation or inspection of the cone crusher that deflects the movable vertebrae (or the deflection of the eccentric sleeve). When the machine is under the condition of full load, the lower edge of the main shaft in pressed on the thicker edge of the taped sleeve that is adjacent to the eccentric shaft, generating the flaws. Usually the flaws on the taped sleeve generates under the circumstance of the empty loading, which severely influence the proper running of the cone crusher. Once there are flaws on the taped sleeve, it should be replaced. Hence, we must know the reason behind the flaw generation before we can find the solution to shot the problem.

Now, lte's talk about the reason of flaw generation of taper sleeve.

1. Unbroken materials come into cone crusher cavity, which is commonly known as the "iron". Light iron can cause crusher failure. Heavy iron can lead to damage of crusher spare parts and motor. The generated impact load can have a strong influence on the taper sleeve.

2. Lubrication issue. Under poor working conditions, the oil contains dust and moisture, oil temperature rising caused by lubrication problem for many times makes spindle locked, taper sleeve burned, which produces internal stress and crack.

3. Reparation and installation issues. Taper sleeve and eccentric shaft aren't closely contact; Two plane of eccentric shaft taper and casting zinc alloy between the two slot do not fill the gap, and receive impact force causing cracks; Taper sleeve is too tight or too loose for the eccentric shaft. When installing mantle, if there is not enough space, the spindle will collide with top part to cause taper sleeve cracking during load run.

4. Uneven feed. Uneven feed causes impacting and vibration, leads to taper sleeve cracking; Unilateral feed cause unbalance feeding, thus generating impacting and vibration to lead taper sleeve cracking.